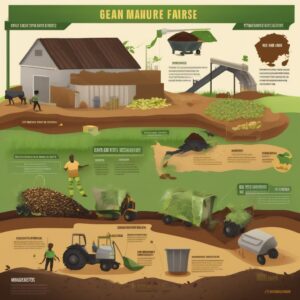

Sustainable waste management on layer farms in Ghana is becoming essential for both environmental health and economic growth. Poultry manure, often seen as waste, can be transformed into valuable resources such as organic fertiliser and biogas. This approach reduces pollution and creates new income streams for farmers, turning manure into profit.

Proper manure collection and handling are crucial in effective and sustainable waste management. Techniques like composting help convert poultry waste into nutrient-rich fertiliser, supporting crop growth and reducing reliance on chemical alternatives. Additionally, biogas production from manure offers a clean energy source that can benefit farms and local communities.

Understanding these methods allows Ghanaian layer farmers to improve their operations while preserving the environment. The growing focus on sustainable farming practices creates opportunities to comply with regulations and explore market possibilities for recycled waste products. This shift supports long-term farm profitability and contributes to a greener future.

Key Takeaways

- Sustainable manure management reduces pollution and adds farm income.

- Composting and biogas production are effective waste treatment methods.

- Waste recycling supports compliance and creates new economic opportunities.

Understanding Sustainable Waste Management in Layer Farms

Sustainable waste management in layer farms focuses on handling poultry waste effectively to prevent pollution and create economic value. It involves knowing the types of waste produced and recognising the benefits and risks associated with poor or good waste handling.

Significance of Sustainable Practices

Sustainable waste management reduces harmful environmental effects and improves farm productivity. Proper waste handling protects soil, water, and air quality by preventing contamination from manure and other farm residues. It also supports animal health and welfare.

Farmers who adopt sustainable practices can reuse waste as fertiliser or biogas, reducing the need for chemical inputs and lowering costs. This approach aligns with global goals for sustainable agriculture and helps farmers meet regulations and market demands for eco-friendly products.

Common Waste Types in Ghanaian Layer Farms

The main waste types from layer farms in Ghana include:

- Manure: Rich in nutrients but can cause pollution if unmanaged.

- Litter and Bedding: Wood shavings or straw mixed with droppings.

- Dead Birds: Require safe disposal to prevent disease.

- Processing Waste: Includes feathers and egg shells.

Manure and litter are the most significant volumes and hold potential for reuse. However, without proper storage and treatment, these wastes pose risks of water contamination and odour problems. Understanding their composition helps farmers choose better handling methods.

Environmental and Economic Impacts

Poor waste management can lead to water pollution, emitting harmful gases like ammonia and methane, which affect local communities and contribute to climate change. Runoff from manure may increase nutrient loads in water bodies, leading to algal blooms and fish kills.

Conversely, turning poultry waste into compost or biogas creates income and energy sources for farms. Compost improves soil fertility, boosting crop yields, and biogas systems reduce reliance on fossil fuels. These benefits highlight waste management not just as an environmental duty but also as a business opportunity.

For more on sustainable poultry waste strategies, see sustainable poultry farming practices.

Manure Collection and Handling Techniques

Manure management in layer farms requires precise methods to collect, store, and control waste effectively. Proper techniques reduce health risks, minimise odours, and preserve the manure’s value as fertiliser or energy source.

Efficient Collection Methods

Layer farms often use deep litter or cage systems that affect collection methods. In deep litter systems, bedding material mixes with manure, which is scooped regularly to prevent build-up and facilitate drying.

Manure belts or scrapers collect droppings daily to prevent accumulation in cage systems. Automated manure belts improve efficiency and reduce labour needs.

Using tools like shovels, wheelbarrows, and conveyors helps move manure quickly. Frequent removal stops moisture and nutrient loss at least once or twice a day.

Efficient collection supports later steps like composting or biogas production, making the process cleaner and more productive.

Safe Storage Practices

Manure must be stored securely to avoid runoff or contamination. Farms often use structures like covered pits, tanks, or sealed containers.

Covered storage blocks rainwater, which can cause leaching and nutrient loss. Solid manure is often kept in heaps or windrows, while liquid manure requires sealed tanks or lagoons.

Proper storage controls moisture content to avoid excessive odour and nutrient loss. It also makes manure ready for use as fertiliser or in biogas systems.

Regular inspection of storage sites ensures that no leaks or pests develop. Safe storage keeps manure contained and maximises its value.

Odour and Pest Management

Odour and pests are significant concerns in manure handling. Effective control maintains farm hygiene and nearby community relations.

Covering manure heaps with straw or plastic sheeting reduces the smell. Adding bulking agents like sawdust can absorb moisture, cutting odours further.

Biological treatments, such as adding beneficial microbes, help break down waste and limit smell.

Farms keep storage areas clean and dry to reduce pests like flies and rodents. Physical barriers such as nets or traps also protect the site.

Good ventilation is essential to stop gas build-up and reduce odours in enclosed spaces. Odour and pest management improve farm conditions and neighbour relations.

More detailed guidance on manure collection and handling systems can be found at Manure Collection and Handling Systems.

Composting Strategies for Poultry Manure

Effective composting of poultry manure involves balancing moisture, oxygen, and temperature to turn waste into valuable fertiliser. Choosing the right composting system and controlling the process helps ensure a high-quality product that benefits soil health and farm profits.

Principles of Composting

Composting breaks down poultry manure using microbes that need air, moisture, and warmth to work well. Moisture should be kept at around 50-60% to support microbial activity without causing foul odours.

Oxygen must be regularly supplied by turning or aerating the pile. This prevents harmful gases and promotes faster decomposition. The temperature should reach 55°C and 65°C to kill pathogens and weed seeds.

A proper carbon-to-nitrogen ratio is essential. Poultry manure is high in nitrogen, so mixing it with carbon-rich materials like straw or sawdust helps balance the pile and avoid nitrogen loss.

Suitable Composting Systems

Different composting methods suit various farm sizes and resources. Windrow composting, where manure is piled in long rows and turned regularly, suits medium to large farms.

For smaller farms, static pile composting with manual aeration works well. Using a Kohshin composter can reduce labour and improve process control.

Another option is vermicomposting, which uses earthworms to break down manure. It produces nutrient-rich compost but requires a stable environment and more management.

To maintain compost quality, farmers should select a system that fits their labour capacity, space, and climate conditions.

Maintaining Compost Quality

Keeping compost quality high needs careful monitoring throughout the process. Regular turning helps maintain oxygen levels and stops foul odours.

Measuring temperature frequently ensures the pile heats enough to kill pathogens but does not get too hot to kill helpful microbes. Moisture must be checked and kept steady by adding water or dry materials.

Testing the final compost for nutrient content and the absence of harmful bacteria helps ensure it is safe and effective as a fertiliser: a dark, crumbly texture and earthy smell mark proper maturity.

Using compost correctly can increase crop yields and reduce fertiliser costs, making it an essential tool for sustainable layer farming in Ghana.

For more on composting benefits, see effective strategies for managing manure.

Nutrient Recovery and Organic Fertiliser Production

Layer manure contains valuable nutrients that can be recovered and transformed into beneficial crop fertiliser. The process includes analysing the manure’s nutrient content, converting it into an organic fertiliser, and using it to improve soil health and crop yields in Ghana.

Nutrient Analysis of Layer Manure

Layer manure is rich in nitrogen (N), phosphorus (P), and potassium (K), which are essential for plant growth. Nitrogen helps leaf and stem development, phosphorus supports root growth and flowering, and potassium improves plant health.

The nutrient levels vary depending on the birds’ diet, manure management, and storage conditions. Tests show that fresh layer manure typically contains 1.5–3% nitrogen, 1–2% phosphorus, and 1.5–3% potassium by weight.

Analysing these nutrients helps farmers understand the right amount of fertiliser needed for different crops. It also prevents over-application, which can harm the environment. Regular testing is key to efficient nutrient recovery and maximising manure value.

Processing Manure into Fertiliser

Transforming layer manure into fertiliser involves composting or anaerobic digestion. Composting breaks down organic matter with oxygen, generating stable, nutrient-rich compost.

The process includes:

- Collecting manure and mixing with carbon-rich materials (e.g., crop residues)

- Managing moisture and temperature for effective microbial activity

- Turning piles regularly to aerate the compost

This can take 2–3 months but results in safer, odour-free fertiliser.

Alternatively, anaerobic digestion produces biogas and digestate, a nutrient-rich liquid valuable crop fertiliser.

Both methods reduce pathogens and weed seeds, producing fertiliser suitable for sale or use on farms. Proper treatment prevents nutrient loss and enhances fertiliser value.

Benefits of Organic Fertilisers for Ghanaian Agriculture

Using organic fertilisers from layer manure improves soil fertility by adding organic matter, which boosts soil structure and water retention. This is crucial in Ghana’s often degraded soils.

Organic fertilisers release nutrients slowly, reducing the risk of nutrient leaching and pollution. They promote beneficial soil microbes, improving nutrient cycling and crop resilience.

Farmers benefit from lower input costs since organic fertilisers can reduce reliance on expensive synthetic products. They also support sustainable farming by recycling waste.

Studies show crops like maize and vegetables respond well to organic fertilisers, with improved growth and yield, making this a practical option for Ghana’s small-scale farmers. For more details, see research on organic fertiliser usage in Ghana.

Biogas Generation from Poultry Waste

Poultry waste has significant potential for producing biogas, a renewable energy source. Using manure through the right processes can reduce waste, cut costs, and supply energy directly to the farm. Effective management can turn poultry waste into valuable fuel and improve farm sustainability.

Anaerobic Digestion Technology

Anaerobic digestion breaks down poultry manure without oxygen, producing biogas mainly made of methane and carbon dioxide. This process occurs in sealed tanks called digesters.

Chicken manure requires careful preparation because it may contain feathers, wood chips, and other materials. These can affect digestion efficiency. The manure is usually mixed with water to create a slurry, which improves microbial activity.

Temperature control is essential. The process works best between 35°C and 40°C, allowing bacteria to break down the waste faster. Depending on conditions, the digestion typically takes 15 to 30 days.

Digesters must be well-sealed to capture methane. Gas can then be stored or used immediately for heating or electricity. This technology reduces harmful odours and pathogens in the manure.

Energy Use and Cost Savings

Biogas from poultry manure can power farm operations, reducing dependence on expensive fuels. It can generate heat for incubators, water heaters, or cooking.

Using biogas often cuts energy bills by 30% or more, depending on farm size. It also lowers costs related to waste disposal and chemical fertilisers since the leftover digested material (digestate) is a natural fertiliser.

Some farms switch to biogas to produce renewable natural gas (RNG), which can be sold or used in vehicles. This creates an additional income stream.

The initial cost of installing digesters varies but is often offset by long-term savings. Grants and support programmes may help with start-up costs in Ghana.

Integrating Biogas with Farm Operations

Integrating biogas systems requires planning to match manure supply with energy needs. Layer farms should estimate manure production and energy demand to size the digester correctly.

Digestate should be used efficiently as fertiliser on crop fields or grasslands to close nutrient loops. Proper storage of digestate prevents pollution.

Biogas systems also improve farm hygiene by reducing manure volume and smell. Training farm workers to manage and maintain the digester is crucial to avoid failures.

Automation can help control temperature, feeding rates, and gas capture, making the system more reliable and easier to operate.

For more details on managing poultry manure for biogas and energy, see effective strategies for poultry waste management.

Commercial Opportunities and Value Addition

Turning poultry manure into profitable products requires creating strong supply chains, identifying markets, and forming strategic collaborations. These steps allow for increasing income from waste while supporting sustainable farming.

Developing Value Chains

Building a value chain for manure-based products involves several key stages: collection, processing, packaging, and distribution. Proper composting techniques increase the nutrient value of poultry manure, making it a desirable fertiliser. Processing facilities should be near layer farms to reduce transportation costs and contamination risks.

Farmers can also explore producing organic fertilisers blended with other waste, adding variety to their offerings. Quality control and certification can help ensure product reliability, attracting buyers who value sustainability. Training farmers to safely handle and process manure is also vital to maintaining product standards.

Market Opportunities for Manure-Based Products

Crop farmers, especially those using sustainable practices in Ghana, are increasingly demanding organic fertilisers. Municipalities and landscaping companies may also seek compost for green spaces. Due to its nutrient content, compost from poultry manure has potential in small-scale and commercial agriculture.

Farmers’ willingness to pay for compost depends on price and perceived benefits. Marketing efforts should highlight cost savings, improved soil health, and reduced chemical use. Value-added products like pelletised fertiliser or liquid extracts can cater to customer segments.

Partnerships for Income Generation

Forming partnerships enhances commercial success by pooling resources and expertise. Collaborations between layer farmers, composting plants, and agricultural input suppliers can streamline production and sales. Local governments and NGOS may offer financial incentives or technical support.

Carbon credit schemes create additional income by rewarding reduced greenhouse gas emissions from organic waste management. Joining networks or cooperatives helps farmers access broader markets and share risks. These partnerships increase the scale and profitability of waste reuse ventures in Ghana.

More details on composting incentives can be found in the Ghana Carbon Market Office report.

Regulatory Compliance and Best Practices

Effective waste management on layer farms requires following the rules that protect the environment and public health. Regulations focus on manure handling, disposal, and the impact of waste on soil and water. Standards set clear limits to reduce pollution and promote sustainable farming.

Ghanaian Waste Management Regulations

Ghana’s waste management laws require farms to handle manure safely to avoid water and land contamination. The Environmental Protection Agency (EPA) monitors waste discharge and enforces penalties for violations.

Farmers must follow guidelines for storing manure to prevent runoff during rain. Proper composting is encouraged to reduce pathogens and odours. Many regulations also demand that farms obtain permits for waste handling, mainly when operating at scale.

Failure to comply can lead to fines or closure. Education and training programmes support farmers in meeting these rules. These efforts aim to improve public health and enable sustainable manure use in agriculture.

Standards for Environmental Protection

Environmental standards set limits on nutrient levels and harmful substances in manure. These rules protect soil quality, prevent water pollution, and reduce greenhouse gas emissions.

Key practices include:

- Covering manure storage to limit ammonia release

- Regular monitoring of soil and water near farms

- Using composted manure for fertilising crops instead of raw waste

These measures help farms minimise environmental risks. Following approved manure management codes supports compliance and enhances farm profitability by turning waste into safe fertiliser. For detailed information on manure management policies in Ghana, see this study on manure management practices.

Challenges and Sustainable Solutions

Layer farms in Ghana face several obstacles to effectively managing poultry waste. Financial limits and technical skills are key issues, while new approaches offer ways to turn manure into profitable products.

Technical and Financial Barriers

Many layer farms struggle with low access to equipment for proper waste treatment. This includes tools for composting, biogas production, or safe storage to prevent pollution. The cost of investing in such technology is often too high for small and medium farms.

Lack of trained personnel worsens the problem. Farmers may not fully understand how to process manure to avoid environmental harm or produce valuable fertiliser. This gap reduces motivation to adopt better practices.

Common barriers include:

- High initial investment costs

- Limited technical training

- Poor infrastructure for waste collection

- Insufficient access to credit or subsidies

Addressing these barriers requires targeted support to improve technical capacity and financial access.

Innovative Models for Ghanaian Farms

Some farms in Ghana are successfully adopting circular economy ideas to manage waste sustainably. They transform manure into organic fertiliser or energy through biogas, improving farm income and reducing environmental impacts.

Partnerships with technology providers and local governments help spread best practices. For example, farms that apply organic fertiliser report better crop yields and market opportunities. Using manure as a resource turns waste into profit.

Key elements of these models:

Element |

Description |

| Waste-to-value tech | Composting, biogas, and manure bioprocessing |

| Farmer training | Workshops and extension services on waste use |

| Financial support | Access to loans, grants, and commercialisation plans |

This approach is gaining attention for its ability to improve sustainability and boost rural economies in Ghana. Adopting these solutions can benefit more farms.

For more on these strategies, see the study on effective manure management in poultry farms and the approach to waste integration in Ghana’s waste system.

Future Prospects for Waste Management in Layer Farms

Sustainable waste management in layer farms in Ghana has strong potential for growth. Advances in technology and increased awareness among farmers can help turn manure from a waste product into a valuable resource.

One promising approach is the development of organic fertiliser production. This can improve soil health while reducing reliance on chemical fertilisers, which are often costly and environmentally harmful. It also creates new income streams for farmers.

Improved manure processing techniques, such as composting and biogas generation, offer clear benefits. Composting stabilises nutrients for crops, while biogas provides renewable energy, reducing farm energy costs and greenhouse gas emissions.

Farmers’ knowledge and training need continuous improvement. Government policies that support education and subsidies can encourage farmers to adopt better waste management practices. Collaborative efforts can also help spread these innovations.

Key future areas to focus on include:

- Expanding access to simple manure treatment technologies

- Promoting market development for organic fertilisers

- Encouraging alliances between farmers and agribusinesses

- Strengthening laws to ensure safe and environmentally friendly waste handling

Table: Benefits of Improved Waste Management Practices

Practice |

Benefit |

Impact |

| Composting | Nutrient-rich fertiliser | Improved crop yields |

| Biogas production | Renewable energy | Lower energy bills |

| Training programs | Better knowledge | Adoption of sustainable methods |

| Policy support | Subsidies and guidelines | Increased farm profitability |

These trends suggest a gradual shift towards turning poultry manure into profit while protecting the environment. The right mix of technology, education, and policy will be vital.

For more about manure management in West Africa, see manure management practices in Ghana and sub-Saharan Africa.

Frequently Asked Questions

Proper handling of poultry manure can turn waste into valuable products like organic fertiliser and biogas. Layer farms in Ghana can improve soil health and reduce pollution if used correctly. Challenges include collection, storage, and finding reliable markets for by-products.

What are the most effective techniques for converting poultry manure into profitable by-products?

Composting is a standard method for stabilising manure and turning it into nutrient-rich fertiliser. Anaerobic digestion can produce biogas, which farms use for energy or sell. Both techniques reduce odours and pathogens while creating marketable products.

How can layer farms in G? How can Hana implement sustainable waste management practices?

Farms should separate manure regularly to avoid contamination. Dedicated composting areas with proper aeration help manage waste effectively. Training workers on best practices improves consistency. Linking with local farmers or buyers for manure sales boosts income.

What is the environment? What are the benefits of proper waste management in layer farming?

Proper manure use reduces Water pollution by preventing runoff into rivers. It lowers greenhouse gas emissions compared to raw waste. Healthy soil improves crop yields, supporting local food systems. Managing manure well also controls smells and pests.

Can adopting sustainable waste management practices impact the profitability of layer farms?

Yes. Selling compost or biogas creates new income streams. Reduced waste disposal costs save money. Healthier birds from better sanitation decrease veterinary bills. These factors combine to improve overall farm profitability.

What are the challenges faced in the utilisation of poultry waste for agricultural purposes?

Storage can be difficult in hot, wet climates, leading to nutrient loss. Lack of awareness limits the adoption of technologies like composting. Infrastructure for processing by-products is often insufficient. Market access for organic fertiliser products remains a hurdle.

What role does government policy play in facilitating sustainable waste management in Ghana’s poultry industry?

Policies can encourage best practices through training programmes and subsidies. Regulations on waste disposal help protect the environment. Support for research and infrastructure development enhances technology adoption. Enforcement of rules ensures farms follow sustainable methods.

For more details on waste management strategies in poultry farms, see Big Dutchman’s article on effective poultry manure management.